Oil Air Separator Vs Catch Can: Comprehensive Guide and Differences in Functionality

Air-oil separators and catch cans are pivotal in the functioning of internal combustion engines. There is a never-ending debate between the oil air separator vs catch can.

An Air-Oil Separator (AOS) separates oil from air and returns oil to the engine. A Catch Can collects oil but doesn’t recirculate it.

The proper functioning of an internal combustion engine relies on a delicate balance of air and fuel, ensuring optimal combustion and, consequently, efficient performance.

One critical aspect that can significantly impact this delicate equilibrium is the prevention of oil contamination in the engine’s intake system. This is where the role of an oil air separator (AOS) and a catch can becomes crucial.

Preservation of Engine Efficiency:

1. Oil Air Separator (AOS):

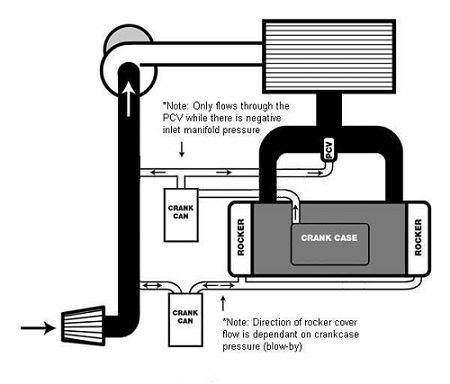

The AOS is designed to separate oil from the air within the Positive Crankcase Ventilation (PCV) system. By preventing oil particles from circulating back into the intake system, it safeguards against the potential buildup of deposits on critical engine components.

This preservation of engine efficiency is paramount, as it ensures that the air entering the combustion chamber remains clean and uncontaminated, allowing for optimal fuel combustion.

2. Catch Can:

The catch can, on the other hand, intercepts and collects oil vapors from the crankcase ventilation system before they can re-enter the intake manifold. This prevents the accumulation of oil in the intake system, reducing the risk of carbon buildup on intake valves and other components.

By capturing and isolating oil contaminants, the catch can contributes significantly to maintaining the engine’s efficiency over time.

Reduction of Carbon Deposits:

1. Oil Air Separator (AOS):

AOS aids in the prevention of oil mist from being released into the atmosphere, reducing the formation of carbon deposits on critical engine surfaces. This reduction is particularly vital for maintaining consistent airflow and combustion.

The minimized carbon deposits lead to cleaner engine components, ensuring optimal performance and longevity.

2. Catch Can:

Catch cans actively reduce carbon buildup by preventing oil vapors from reaching the intake valves. This, in turn, mitigates the risk of reduced airflow, diminished combustion efficiency, and potential misfires.

The catch can’s role in reducing carbon deposits enhances the overall efficiency and reliability of the engine.

Read More About Can You Add Zinc To Synthetic Oil: Exploring The Possibility

Prolonged Engine Lifespan:

1. Oil Air Separator (AOS):

The AOS’s ability to separate oil from the air-oil mixture and direct it back to the engine or oil pan contributes to prolonged engine life. This is achieved by maintaining the lubrication system’s integrity and preventing excessive wear on vital engine components.

Preserving the engine’s lifespan is a direct result of the AOS’s effective oil separation mechanism.

2. Catch Can:

The catch can, by preventing oil accumulation, plays a key role in reducing wear and tear on engine components. This contributes to the overall longevity of the engine, minimizing the need for premature repairs or replacements.

The catch can’s impact on engine lifespan underscores its significance in long-term engine health.

In this comprehensive guide, we’ll delve into the distinctions between an air-oil separator and a catch can.

What Is The Difference Between Air-Oil Separator Vs Catch?

Below is a table outlining the primary differences between an Air-Oil Separator and a Catch Can:

| Feature | Air-Oil Separator | Catch Can |

| Purpose | Separates oil from air in the PCV system | Collects oil and moisture from the PCV system |

| Functionality | Uses a series of baffles and chambers to separate oil from the air | Uses a mesh or filter media to trap oil vapors |

| Oil Reclamation | Often returns the separated oil to the oil pan/engine | Requires periodic draining to remove collected oil |

| Maintenance | Generally low maintenance | Requires periodic emptying and cleaning |

| Oil Recirculation | May recirculate clean air back into the intake | Generally does not recirculate air, oil is trapped and collected |

| Installation | Typically more complex, integrated into the engine’s PCV system | Generally easier to install, often aftermarket |

| Cost | Typically more expensive | Generally more affordable |

| Efficiency | Often more efficient at removing oil from the air | Depending on the design; efficiency can vary |

| Application | Commonly found in performance or high-efficiency engines | Can be used in various types of engines |

What Is Air Oil Separator?

An air-oil separator is a device used in machinery to separate compressed air from oil mist, ensuring clean air output. It prevents oil contamination in compressed air systems, enhancing equipment performance and longevity.

What Is Inside An Oil Separator?

An oil separator typically contains an oil gathering zone for initial collection, a demisting zone to remove fine oil droplets, a liquid zone where separated oil settles, and a gas zone for clean gas exit.

What Is The Structure Of Air Separator?

An air separator typically comprises a “four-end” type membrane, a counter-flow air heater, an expander air compressor, and an electric generator. This setup allows for efficient separation and utilization of air components in various industrial applications.

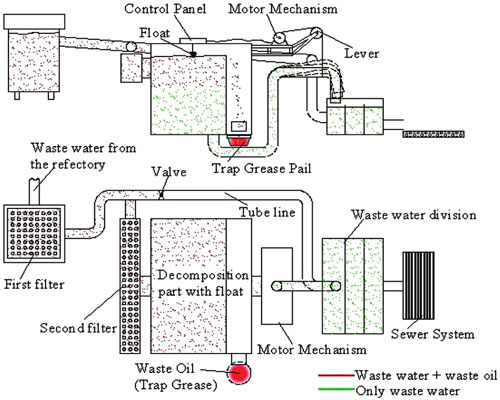

Oil Air Separator Diagram

What Are The Two Types Of Air Separators?

Automatic Air Separators and Mechanical Air Separators are two types used to remove air from heating and cooling systems. The Automatic variety uses float or air vent mechanisms, while Mechanical separators rely on centrifugal force to eliminate air bubbles.

What Does Air Oil Separator Do?

An air-oil separator is a device used in internal combustion engines and industrial applications to separate oil from the air-oil mixture. It prevents oil mist from being released into the atmosphere, reducing pollution and maintaining engine efficiency.

What Is The Function Of Oil Separator?

An oil separator functions to separate oil from the refrigerant vapor in a refrigeration or air conditioning system. This ensures that the compressor receives only refrigerant vapor, while the lubricating oil is returned to the compressor’s crankcase, maintaining optimal system performance and component longevity.

How Does A Oil Separator Work?

An oil separator works by:

- Directing wastewater from filters into the separator.

- Guiding the wastewater through chambers.

- Using these chambers to separate oil, water, and sludge.

- Allocating each substance into distinct spaces for collection.

Where Are Air Separators Used?

Air separators are used particularly in areas where pressure is low and temperature is high.

What Happens When An Air Oil Separator Fails?

When an air oil separator fails, several potential consequences can arise.

- Increased Oil Consumption

- Reduced Efficiency

- Contaminated Air Discharge

- Increased Maintenance

- Reduced Equipment Lifespan

- Potential Safety Hazards

- Environmental Concerns

- Increased Operating Costs

- Loss of System Integrity

- Compliance Issues

How Do You Size An Air Separator?

- Establish the desired efficiency for the air separator.

- Identify the corresponding percentage of maximum capacity based on the chosen efficiency.

- Divide the flow rate by this percentage to determine the appropriately sized air.

How Do You Separate Oil And Air?

To separate oil and air, several techniques can be used:

- Filtration: Using porous materials or membranes to trap oil droplets while allowing air to pass through.

- Coalescing: Encouraging oil droplets to merge and form larger droplets for easier removal.

- Impingement: Directing the mixture against surfaces to cause droplets to separate by inertia.

How Do You Calculate Oil Separator?

To calculate the oil separator:

- Identify design flow Qm in M3/Hr.

- Determine horizontal separator area AH in M2.

- Obtain oil droplet diameter μ2 in microns.

- Find the specific gravity of wastewater Sw and oil phase S∘.

- Know wastewater’s dynamic viscosity ϕ in poise.

- Use the formula: Qm/(AH×7.48)=(μ2×1.072×10 −6 )(Sw−S∘)/ϕ.

Read Also 9 Best Oil For 4 Stroke Dirt Bike For Performance & Protection

How Do You Install An Air Separator?

Here’s a general guide on how to install an air separator:

Step 1: Choose the Right Location:

Place the air separator at a location where air is most likely to accumulate, typically at high points in the system or near the boiler outlet.

Step 2: Isolate the System

Shut off the system and drain the water to prevent any accidents or water damage.

Step 3: Prepare the Installation Site

If you’re installing a new air separator, follow the manufacturer’s recommendations for any specific preparations.

Step 4: Install the Air Separator

Mount the air separator vertically with the flow direction marked on the device. Use the appropriate fittings and ensure it’s securely fastened.

Step 5: Connect Piping

Connect the system piping to the inlet and outlet of the air separator. Use the appropriate fittings, and ensure all connections are tight to prevent leaks.

Step 6: Install Valves

Install isolation valves on both the inlet and outlet sides of the air separator. This allows for easier servicing or replacement in the future without draining the entire system.

Step 7: Fill and Purge the System

Refill the system with water and ensure all air vents are open. Start the system and allow it to run. Open the air vents one by one to purge any trapped air until only water flows out.

Oil Air Separator Replacement

- Locate the Separator

- Drain Oil

- Disconnect Hoses

- Unbolt the Separator

- Inspect & Clean

- Install New Separator

- Refill Oil

- Check for Leaks

- Test Drive

What Is An Occ (Oil Catch Can)?

An Oil Catch Can (OCC) is a device installed in a vehicle’s crankcase ventilation system to trap and separate oil vapors from the air. It prevents oil accumulation in the intake system, reducing carbon buildup and maintaining engine efficiency.

Types of Oil Catch Cans

Here are some common types:

- Basic Catch Cans

- Baffled Catch Cans

- Vented Catch Cans

- Recirculating Catch Cans

- Engine-Specific Catch Cans

- Universal Catch Cans

What Does An Oil Catch Can Do?

An oil catch can intercepts and collects oil and moisture vapors from the crankcase ventilation system before they can re-enter the intake manifold. This prevents oil buildup in the engine, reduces carbon deposits, and maintains optimal engine performance.

Where Is The Catch Can?

The catch can is typically installed in the line of the crankcase breather system. Its purpose is to capture oil and moisture before they can enter the intake manifold.

Why Are Oil Catch Cans Illegal?

- Modifying Emission Systems: Altering emissions systems can lead to increased pollutants, undermining vehicle standards and environmental protection measures.

- Illegal Modifications: Some oil catch can installations might violate specific regulations governing vehicle modifications, leading to legal repercussions.

- Pollution: Improperly installed or maintained oil catch cans can release trapped pollutants into the atmosphere, contributing to air pollution.

- Environmental Risk: The release of unfiltered gases or liquids from malfunctioning catch cans poses ecological threats to local habitats and ecosystems.

Oil Catch Can Pros And Cons

Pros of Oil Catch Cans

- Reduces Carbon Build-Up: By capturing oil and other contaminants, catch cans help prevent carbon deposits from forming on the intake valves.

- Extends Engine Life: Catch cans can help reduce wear and tear on engine components, potentially extending the engine’s lifespan.

- Maintains Performance: A cleaner intake system can help maintain the engine’s performance.

- Reduces Maintenance: Catch cans can help reduce the frequency of maintenance tasks such as cleaning intake valves and replacing spark plugs.

- Environmental Benefits: By capturing oil and contaminants, catch cans help reduce harmful emissions from the engine, contributing to a cleaner environment.

Cons of Oil Catch Cans

- Installation Complexity: Installing an oil catch may require modifications to the engine’s crankcase ventilation system, which can be complex and time-consuming.

- Maintenance Requirements: Oil catch cans require regular maintenance to empty and clean the collected oil and contaminants.

- Potential for Overfilling: If not checked and emptied regularly, catch cans can overfill, leading to oil and contaminants being pushed back into the intake system and potentially causing damage.

- Cost: Quality oil catch cans can be relatively expensive.

What Is The Difference Between 1 And 2 Oil Catch Cans?

A Single Valve PCV Oil Catch Can capture oil during idle, while a Dual Catch Can has separate ports for idle and throttle-induced vacuum to capture oil effectively.

Difference Between Single and Dual Oil Catch Cans:

Oil catch cans, sometimes referred to as single and dual catch cans or single and dual valve catch cans, play a crucial role in preventing oil vapors from re-entering the intake manifold and contributing to carbon buildup.

The primary difference between a single and dual oil catch can lies in the number of chambers or valves dedicated to the separation and collection of oil vapors.

While a single catch can is straightforward and suitable for standard applications, a dual catch can offers enhanced efficiency, making it preferable for high-performance or forced-induction engines where varying pressure conditions are more prevalent.

1. Single Oil Catch Can:

- Configuration: A single oil catch can features a single chamber for capturing and collecting oil vapors from the crankcase ventilation system.

- Functionality: In a single catch can setup, all the oil vapors are directed through a single pathway for separation and collection.

- Application: Typically, a single oil catch can is suitable for standard or moderate-performance engines with relatively lower crankcase pressures.

- Advantages: Simplicity in design and installation. Well-suited for engines with lower oil blow-by.

- Consideration: While effective for many applications, a single catch can may reach its capacity sooner in high-performance or turbocharged engines.

2. Dual Oil Catch Can (Dual Valve Catch Can):

- Configuration: A dual oil catch can system incorporates two separate chambers or valves for the collection of oil vapors.

- Functionality: The dual configuration allows for a more comprehensive separation process, often dedicating one chamber to handle low-pressure situations, such as during idle, and the other for higher-pressure scenarios, such as throttle-induced vacuum during acceleration.

- Application: Dual catch cans are commonly employed in high-performance, turbocharged, or supercharged engines where there’s a higher likelihood of increased crankcase pressure.

- Advantages: Improved oil vapor separation efficiency, especially in engines with varying pressure conditions. Enhanced capacity to handle a broader range of driving conditions.

- Consideration: Dual catch cans provide greater flexibility and efficiency but may involve a more complex installation process.

What Is The Difference Between A Catch Can And A Pcv?

A catch can is an auxiliary device installed in the breather system to collect oil and moisture before it reaches the intake, preventing carbon buildup. The PCV (Positive Crankcase Ventilation) system, on the other hand, manages crankcase emissions to improve engine efficiency and reduce pollution.

Why Not To Use A Catch Can?

While catch cans offer benefits in terms of preventing oil contamination in the intake system, there are certain considerations and potential drawbacks associated with their use. Here are reasons why someone might hesitate or decide not to use a catch can:

1. Modification Complexity:

Reason: Installing a catch can might require modifications to the engine’s crankcase ventilation system, and not all users are comfortable or knowledgeable about making such modifications.

2. Maintenance Requirements:

Reason: Catch cans need regular maintenance to empty and clean the collected oil and contaminants. Some users may find this additional maintenance task cumbersome.

3. Potential for Overfilling:

Reason: If not checked and emptied regularly, catch cans can overfill. This can lead to oil and contaminants being pushed back into the intake system, potentially causing damage.

4. Cost:

Reason: Quality catch cans can be relatively expensive. Some users may be reluctant to invest in a catch can, especially if they perceive the cost as high compared to the perceived benefits.

5. Engine Design:

Reason: Certain modern engines are designed with efficient Positive Crankcase Ventilation (PCV) systems that adequately manage crankcase gases without significant oil buildup. In such cases, users might question the necessity of adding a catch can.

6. Potential Legal Issues:

Reason: In some regions or jurisdictions, modifying emission systems, which includes installing catch cans, might violate specific regulations governing vehicle modifications. This could lead to legal repercussions or issues during vehicle inspections.

7. Pollution Concerns:

Reason: If catch cans are improperly installed or not maintained, they can release trapped pollutants into the atmosphere. This contributes to air pollution and poses environmental risks.

8. Environmental Impact:

Reason: Improperly maintained catch cans can lead to the release of unfiltered gases or liquids, posing ecological threats to local habitats and ecosystems.

9. Unproven Performance Benefits:

Reason: In some cases, users may question the actual performance benefits of catch cans, especially if their vehicle operates under standard driving conditions and doesn’t experience excessive oil blow-by.

Oil Catch Can Diagram:

1. Inlet Hose:

This is the hose connected to the Positive Crankcase Ventilation (PCV) system or breather port on the engine. It allows the flow of air and oil vapors into the catch can.

2. First Chamber:

he first chamber of the catch can is the initial collection point. As the air-oil mixture enters, it encounters baffles or a mesh system designed to slow down the airflow and allow oil droplets to condense.

3. Baffle System:

The baffle system within the first chamber helps separate heavier oil droplets from the air. It induces changes in airflow direction, causing the oil to impact and collect on the walls of the chamber.

4. Drain Plug:

At the bottom of the first chamber, there is a drain plug. This allows for periodic draining of the collected oil. Some catch cans may have a transparent section or indicator to show the level of accumulated oil.

5. Second Chamber:

The second chamber serves as a secondary collection point. It may contain additional baffles or filter media to further refine the air and capture any remaining oil particles.

6. Outlet Hose:

The outlet hose is connected to the clean side of the PCV system or the intake manifold. It allows the filtered and oil-free air to be recirculated back into the engine for combustion.

7. Vent/Fill Cap:

The top of the catch can may have a vent or fill cap. This provides access for maintenance and draining. Some designs may include a breather filter here.

Remember, catch can designs can vary, and some may have additional features such as check valves, baffles, or filters in different configurations. The purpose of the catch can is to capture and separate oil from the crankcase ventilation system, ensuring cleaner air enters the engine for combustion.

Catch Can Replacement

If you’re replacing a catch can:

- Ensure the engine is cool.

- Disconnect the old can.

- Fit the new can in the same location.

- Reconnect hoses.

- Secure with clamps.

- Test for leaks.

- Dispose of old cans responsibly.

How To Install A Oil Catch Can

Here’s a general guide on how to install an oil catch can:

Step 1: Locate a Mounting Spot

Choose a location for the oil catch can. It should be easily accessible and away from excessive heat sources.

Step 2: Prepare the Area

Ensure that the chosen mounting area is clean and free from any obstructions.

Step 3: Install Mounting Brackets

If your catch can come with mounting brackets, attach them to the catch can according to the manufacturer’s instructions.

Step 4: Route Hoses

- Identify the PCV (Positive Crankcase Ventilation) valve or breather on your engine.

- Disconnect the hose(s) leading from the PCV valve to the intake manifold.

- Attach a new hose from the PCV valve to the input side of the oil catch can.

- Attach another hose from the output side of the catch can to the intake manifold or intake system.

Step 5: Secure Hoses

Use hose clamps to secure the hoses to the fittings on the catch can and the engine components. Ensure a tight seal to prevent any leaks.

Step 6: Check Clearances

Make sure that the hoses are not kinked or touching any hot components. Ensure there’s enough clearance for any moving parts or engine movement.

Step 7: Double-Check Connections

Before starting the engine, double-check all connections to ensure they are secure and properly routed.

Step 8: Start the Engine

Start the engine and let it idle for a few minutes. Check for any leaks around the connections and hoses.

When Should I Install A Oil Catch Can?

Here are some situations and reasons when you might consider installing an oil catch can:

- Direct Injection Engines: Modern direct injection engines are more prone to oil blow-by due to increased crankcase pressures.

- Turbocharged or Supercharged Engines: Forced induction systems can increase crankcase pressure, leading to more oil blow-by.

- High-Performance Applications: Vehicles used for racing or high-performance driving often generate higher crankcase pressures.

- Prevent Carbon Build-Up: Installing a catch can can help reduce carbon build-up, which can improve engine efficiency and longevity.

- Prolonged Engine Life: An oil catch can contribute to prolonging the life of engine components.

- Custom Builds and Modifications: If you are building a custom vehicle or making modifications that increase crankcase pressure, installing an oil catch can be a proactive measure to protect the engine and maintain performance.

How Do You Know When A Catch Can Is Full?

Here are some signs to look for when determining if a catch can is full:

- Physical Check: By checking the level against the marked lines, you can determine if it’s full or nearing capacity.

- Engine Performance: If the catch can is full, the engine might show signs of decreased performance, rough idling, or even stalling.

- Increased Odor: A full catch may result in increased odors coming from the engine compartment or exhaust due to the accumulation of oil and contaminants.

- Loss of Efficiency: As the catch can fill, its efficiency in separating oil and contaminants from the crankcase ventilation system decreases.

Oil Air Separator Vs Catch Can: Compatibility

1. Oil/Air Separator

They are generally compatible with the engine’s existing systems and are designed to function seamlessly without causing any issues.

2. Catch Can

Catch cans are generally designed to be compatible with a wide range of vehicles. However, the specific design and installation requirements may vary depending on the vehicle’s make and model.

Which One Should I Choose For My Car?

Both the Air-Oil Separator and Catch Can aim to prevent oil contamination of the intake system and reduce carbon buildup on engine components. However, they achieve this through different mechanisms and designs.

Your choice between the two would depend on your specific needs, budget, and the type of engine application.

FAQs

How does oil separator work in air compressor?

An oil separator in an air compressor removes oil from compressed air. It uses centrifugal force and filtration to separate oil droplets, ensuring clean, oil-free air for applications.

Do oil catch cans reduce performance?

Oil catch cans do not reduce performance; rather, they help improve engine efficiency by capturing oil vapors and preventing them from entering the intake system.

Does catch can add horsepower?

A catch can does not directly add horsepower. Its primary function is to capture and prevent oil vapors from re-entering the intake, but it does not increase engine power.

Does a catch can reduce Blowby?

Yes, a catch can reduce blowby by capturing and separating oil and other contaminants from the crankcase ventilation system, preventing them from entering the intake system.

What is first stage separator?

A first-stage separator is an initial component in oil and gas processing that separates gas from crude oil or water, typically through gravitational or centrifugal force.

How many types of oil separators are there?

There are two main types of oil separators: the oil/gas/water three-phase separator and the gas/liquid two-phase separator.

Conclusion

The debate between the Oil Air Separator vs Catch Can has been both enlightening and contentious. While both devices aim to reduce the amount of oil vapors that re-enter the engine’s intake, their methods and efficiency levels differ. The choice between the two largely depends on specific vehicle needs, driving habits, and performance goals.