Refining Gasoline: From Crude to Car

Refining gasoline is a fascinating process that uses science to break down crude oil and create the different fuels we rely on every day.

Refining gasoline isn’t magic, but it is a complex transformation! Have you ever wondered how that raw, crude oil gets turned into the fuel that powers your car?

Let’s dive into the refinery and explore the magic (or should we say science?) behind refining gasoline!

Refined Petroleum Products

There are thousands of refined petroleum products, but some of the most common include:

1. Fuels

Gasoline, diesel fuel, heating oil, jet fuel, propane, and butane. These are all burned as fuel to provide heat and power our cars, trucks, airplanes, and homes.

2. Petrochemicals

These are the basic building blocks for many chemicals used to make a wide variety of products, including plastics, fibers, solvents, and medications.

3. Asphalt

Used in paving roads and roofing.

4. Lubricants

Used to reduce friction between moving parts in machines and engines.

5. Wax

Used in candles, cosmetics, and food packaging.

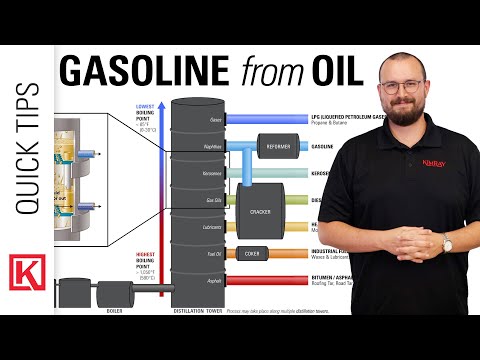

Crude Oil Refinery Process Flow Diagram

The diagram below shows a simplified flow diagram of a typical crude oil refinery:

1. Desalting

Crude oil is first desalinated to remove salt and other impurities. Salt can damage refinery equipment and can also cause corrosion.

2. Atmospheric Distillation

The desalted crude oil is then heated in a furnace and fed into a distillation tower. The tower is a tall column with several trays or plates inside. As the crude oil rises up the tower, it cools and condenses into different fractions.

3. Vacuum Distillation

The atmospheric residue from the atmospheric distillation tower can be further processed in a vacuum distillation unit to separate it into lighter fractions that can be used to make gasoline, diesel fuel, and other products.

4. Cracking

Cracking breaks down large hydrocarbon molecules into smaller molecules that can be used to make gasoline and other transportation fuels.

5. Reforming

Reforming rearranges the molecular structure of hydrocarbon molecules to produce high-octane gasoline.

6. Alkylation

Alkylation combines small hydrocarbon molecules to produce high-octane gasoline.

7. Hydrotreating

Hydrotreating removes sulfur, nitrogen, and other impurities from hydrocarbon streams.

8. Product Blending

The final step in refining crude oil is product blending. The various product streams from the conversion units are blended together to meet product specifications. For example, gasoline is blended to meet a certain octane rating.

Refining Of Petroleum Class 8

Crude oil, a mix of ingredients, isn’t directly usable. In refineries, magic (science!) separates them based on boiling points. This refines petroleum into fuels, plastics, and more!

Types Of Refinery

- Refineries aren’t one-size-fits-all! There are four main types, each with a complexity level:

- Topping Refinery (Simplest): Separates crude oil into basic groups like gasoline and fuel oil using distillation.

- Hydro-Skimming (A Step Up): Similar to topping, but adds a cleaning process to improve gasoline quality.

- Conversion Refinery (More Complex): Uses additional processes to convert heavier oil fractions into lighter, more valuable products like gasoline.

- Deep Conversion Refinery (The Most Complex): Combines conversion techniques with coking units to squeeze every drop of usefulness from crude oil, maximizing lighter products.

How Refineries Work

Refineries transform gooey crude oil into fuels and everyday items! Crude oil, a mix of molecules, gets heated and separated in a tall tower based on boiling points.

Lighter components become gasoline, while heavier ones turn into diesel or heating oil. Further processes convert some parts, and finally, everything gets blended to create the final products we use!

What Chemicals Are Used To Refine Gasoline?

Refining uses heat, pressure, and catalysts like acids or metals. These break down large oil molecules or combine smaller ones to create gasoline.

What Are The Five Basic Refining Processes?

The five basic refining processes are:

1. Separation (by Absorption or Distillation)

This is the first step in refining crude oil. It separates the crude oil into various fractions based on their boiling points. Distillation towers are used to achieve this separation.

Lighter fractions with lower boiling points rise to the top of the tower and condense into liquids, while heavier fractions with higher boiling points condense lower in the tower.

2. Cracking

There are two main types of cracking: thermal cracking and catalytic cracking. Thermal cracking uses heat to break down the molecules, while catalytic cracking uses a catalyst to speed up the process and produce a higher yield of gasoline.

3. Reshaping

Reshaping, also known as reforming, rearranges the molecular structure of hydrocarbon molecules to produce high-octane gasoline. This process is important because it improves the quality of gasoline and reduces engine knocking.

4. Combining

Combining, also known as alkylation, combines small hydrocarbon molecules to produce high-octane gasoline. Alkylation is an important process for increasing the production of gasoline from a barrel of crude oil.

5. Treating

Treating removes impurities like sulfur, nitrogen, and oxygen from hydrocarbon streams. These impurities can damage refinery equipment and can also cause air pollution when the fuels are burned.

What Is Refinery?

A refinery is a factory that transforms crude oil like magic into useful products. Inside, giant towers separate oil by boiling point, and other processes turn it into gasoline, plastic, and more!

Refining Gasoline In Usa

Across 30 US states, refineries transform crude oil. Using heat and science, they separate and reshape molecules, creating gasoline and other fuels that power our nation.

Refining Oil Into Gasoline

Refining oil for gasoline is like a chemistry kitchen! Crude oil separates by boiling point, then big molecules are cracked into smaller ones like gasoline, with some cleaning to make it engine-ready.

Refining Diesel Vs Gasoline

| Features | Gasoline | Gasoline |

| Chemical Makeup | Heavier hydrocarbon chains (15-20 carbon atoms) | Lighter hydrocarbon chains (5-12 carbon atoms) |

| Boiling Point | Higher boiling point | Lower boiling point |

| Distillation Process | Lower yield from crude oil | Higher yield from crude oil |

| Further Processing | May require less processing after distillation | Requires additional processing (cracking, reforming) to improve quality |

| Emissions | Can produce more particulate matter (soot) | Can produce more smog-forming hydrocarbons |

Refining Gasoline From Crude Oil

- Separation: Crude oil gets heated and pumped into a distillation tower. Lighter components with lower boiling points rise and condense as gasoline fractions.

- Straight Run Gasoline: The initial gasoline isn’t perfect, collected as “straight run” gasoline.

- Conversion: Heavier fractions go through cracking, breaking them into smaller gasoline-sized molecules.

- Treatment: Impurities like sulfur are removed to meet environmental regulations.

- Blending: Different gasoline fractions are mixed to achieve the desired octane rating and performance.

- Finished Product: The gasoline is then stored and transported for use in vehicles.

Refining Gasoline From Petroleum

- Desalting: The oil gets a quick wash to remove salty water and impurities.

- Distillation: Crude oil enters a hot tower, separating into fractions based on boiling points. Lighter gasoline components rise and condense first.

- Cracking: Heavier leftover oil gets broken down into smaller gasoline-sized molecules with heat and catalysts.

- Reforming (optional): Straight-run gasoline may undergo a reshaping process to improve its quality for better engine performance.

- Treating: Chemicals remove unwanted sulfur and other impurities to meet clean fuel standards.

- Blending: The final step! Different gasoline streams are mixed to achieve the desired octane rating and performance characteristics.

Refining Gasoline Production

rude oil gets separated by boiling point. Lighter fractions rise and condense as gasoline, while heavier ones become other products. This complex process squeezes valuable fuel from raw oil.

Co2 Emissions Refining Gasoline

Refining gasoline itself doesn’t create the bulk of CO2 emissions. The real impact comes from burning the fuel. However, the refining process does release CO2 from burning fuel to power the facilities and from venting gases during separation.

Is Diesel A Byproduct Of Refining Gasoline?

Nope! Diesel and gasoline are both main products from refining, not leftovers. Crude oil gets separated by boiling point, with diesel’s heavier molecules requiring a higher temperature to vaporize during distillation. They each play a specific role, powering different vehicles!

Is Diesel Fuel A Byproduct Of Refining Gasoline?

Diesel isn’t leftover from gasoline production! Both are key products from refining crude oil. Diesel comes from heavier oil molecules, requiring less processing than gasoline’s lighter ones.

Think of it as sorting Legos – diesel is the bigger bricks, gasoline the smaller ones, and the refinery sorts them all out!

Is The Final Step In Refining Gasoline?

The final step in refining gasoline isn’t a single process, but rather blending. Here, various gasoline streams are mixed to achieve the desired properties like octane rating and vapor pressure, ensuring a clean-burning and efficient fuel for your car.

Price Of Refining Gasoline

The exact cost of refining gasoline isn’t fixed, but ranges between 40 and 70 cents per gallon. It depends on factors like the crude oil type, processing technology, and even seasonal fuel blends.

By Product Of Refining Gasoline

Refining gasoline isn’t just about fuel! Besides gasoline itself, byproducts like liquefied petroleum gas (LPG) for cooking, and lighter fractions for plastics and other materials come from the process.

Refining Oil Into Gasoline Is What Type Of Economy?

Refining oil into gasoline isn’t directly linked to economic types (primary, secondary, etc.). It’s an activity within the secondary sector. This sector focuses on transforming raw materials (like crude oil) into finished goods (like gasoline).

Refining Diesel Fuel Vs Gasoline

Both diesel and gasoline come from crude oil, but the refinement differs. Diesel fuel starts heavier, requiring less processing after distillation. Gasoline, lighter initially, needs more cracking and reforming to be usable. This difference shapes their properties – diesel packs more energy for trucks, while gasoline ignites easier for cars.

Refining Costs Gasoline

Refining isn’t gasoline’s biggest cost, but it matters! It depends on the type of gasoline (summer/winter blend) and can range from 40 to 70 cents per gallon. This cost sits alongside crude oil price, taxes, and distribution fees to make up the price at the pump.

Alternatives To Petroleum Refining Processes

There’s a push for alternative processes. Here are some promising areas of exploration:

1. Biomass Refining

This process uses renewable organic materials like plants, algae, and waste products to create biofuels. Biomass can be converted into liquid fuels through processes like fermentation or gasification.

2. Direct Conversion

This group of technologies aims to convert natural gas or other resources directly into fuels or chemicals, bypassing the need for traditional refining altogether. Techniques include gas-to-liquids (GTL) and methanol-to-gasoline (MTG).

3. Electrofuels

These are synthetic fuels produced using renewable electricity and captured carbon dioxide. Electrolysis splits water into hydrogen, which can then be combined with CO2 to create synthetic fuels or chemicals.

4. Advanced Catalytic Processes

Researchers are developing new catalysts that can improve the efficiency and environmental impact of existing refining processes. These catalysts can enable more selective conversion of crude oil fractions or reduce emissions from the process.

Refining Gasoline Diy

Refining gasoline yourself is extremely dangerous! It involves flammable liquids, high temperatures, and toxic fumes. Leave gasoline production to professionals and consider safer alternatives for your vehicle.

Refining Gasoline At Home

Refining gasoline at home is extremely dangerous and not recommended. It requires specialized equipment and knowledge to handle volatile materials safely. It’s much safer to purchase gasoline from a licensed station.

Refining Gasoline Equipment Diy

- Distillation Tower: Separates crude oil into various fractions, including gasoline

- Cracker: Breaks down heavier hydrocarbons into lighter ones through high temperature and pressure

- Reformer: Improves the octane rating of gasoline through a catalytic process

- Alkylation Unit: Increases gasoline production by combining lighter hydrocarbons

Gasoline Is Produced By Refining

Crude oil is the starting point, and refining separates it into usable products like gasoline.

Gasoline Is Produced By Refining Ethanol

Actually, it’s the other way around! Ethanol is an alcohol fuel, often blended with gasoline, but not its source. Gasoline comes from refining crude oil.

Gasoline Is Produced By Refining Units

Gasoline isn’t “made” from scratch. Refining units separate & process crude oil to get gasoline. Think of it like sorting Legos: the unit separates the crude oil mix into its useful parts, with gasoline being one.

Gasoline Is Produced By Refining Butanol

Actually, it’s the other way around. Gasoline is the main product, and butanol can be blended with it as an additive. Butanol itself can be produced from various sources including corn.

Gasoline Is Produced By Refining Biofuels

It’s not quite right (gasoline usually comes from crude oil), biofuels can be converted into gasoline-like fuels! Imagine using a special furnace to break down plant matter (biomass) into bio-oil. Then, through a process like hydrocracking, that bio-oil can be transformed into molecules similar to gasoline for your car.

FAQs

What is the first step in petroleum refining?

The first step separates crude oil by boiling point in a large tower called a distillation unit. Lighter fractions rise and condense into different fuels.

Why is petroleum called black gold?

Petroleum is valuable because it refines into gasoline, diesel, and other essential products, making it a highly sought-after resource.

What catalyst is used in gasoline production?

Catalytic cracking uses a special material, often containing platinum, to speed up the breakdown of heavy oil molecules into gasoline.

Is ethanol in gasoline?

Some gasoline contains ethanol, an alcohol fuel made from plants. This can reduce reliance on crude oil and emissions.

What liquid is used to make gasoline?

Gasoline isn’t made from a single liquid. Crude oil, a complex mixture of hydrocarbons, is refined through distillation and conversion processes to create gasoline.

What is a refinery catalyst?

A refinery catalyst is a substance that accelerates chemical reactions in the refining process. For instance, it can increase gasoline yield or improve its quality.

What is the main source of gasoline?

The main source of gasoline is crude oil, a fossil fuel found underground. Refining separates crude oil into various fuels and chemicals.

Conclusion

Refining gasoline is fascinating! We’ve explored the key steps, from cracking heavy oils to blending final products. While the process is complex, it underpins how we power our vehicles and much more. As technology advances, refining gasoline will likely continue to evolve, but for now, it remains an essential process in our modern world.